Contact Us

Contact Us

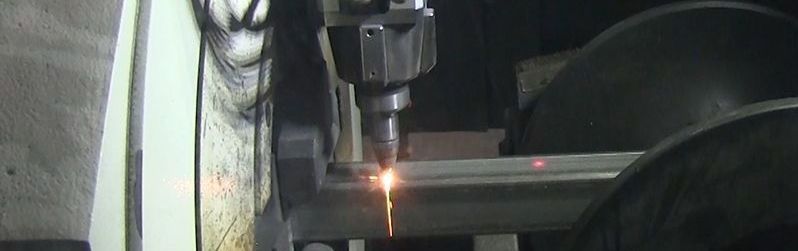

At RITZ Machine Works Inc., we deliver precision tube bending in Plymouth, Minnesota for OEMs and manufacturers across transportation, agriculture, and recreational industries. Our state-of-the-art facility combines advanced CNC mandrel tube bending with complementary capabilities to produce complex bent assemblies that meet exact specifications.

Let's discuss how we can solve your tube bending challenges together.

Quality Issues Compromising Your Manufacturing Timeline?

When your production schedule depends on tubular components that arrive on time and fit perfectly the first time, settling for inconsistent quality creates costly bottlenecks. Manufacturing delays compound when bent assemblies require rework or replacement, disrupting your entire supply chain and putting customer commitments at risk.

Our tube bending solutions eliminate these frustrations through precision manufacturing processes that deliver dimensional accuracy and repeatable results. We handle everything from prototyping to high-volume production runs, ensuring your components arrive ready for assembly without modifications or adjustments that drain resources and delay deadlines.

How Do Smooth Radius Bends Optimize Exhaust Flow?

Exhaust systems demand more than basic fabrication when performance, emissions compliance, and durability intersect. Our tube bending in Plymouth, Minnesota produces smooth, tight radius bends that optimize flow characteristics while maintaining structural integrity under extreme temperatures and vibration.

Each exhaust component receives precision attention through our custom tube bending processes that accommodate complex routing requirements in confined spaces. We produce mitered tips, insulated assemblies with heat shield options, and specialized connections that meet your exact specifications.

Why Choose Structural Tubing for Heavy-Duty Frame Applications?

Structural applications require tubular components that deliver strength, precise fit, and long-term durability across chassis assemblies, door frames, and mounting structures. Our tube bending in Plymouth, Minnesota capabilities produce large radius elbows and complex bent sections that maintain material properties throughout the forming process.

From bumper assemblies to handrail systems, our structural bent tubing combines stainless steel tube bending and carbon steel processing with CWB-certified welding to create integrated assemblies ready for installation. Our approach emphasizes dimensional consistency across production runs, so replacement parts match original specifications years down the line.

Connect with our engineering team for technical support and solutions.

Tube Bending in Plymouth, Minnesota Delivers Compact Coolant Solutions

Engine compartments present manufacturing challenges that separate capable tube bending operations from those truly equipped to handle precision work. When space constraints and performance specifications converge, our tube bending in Plymouth, Minnesota routes fluids and air efficiently through tight quarters without compromising flow or reliability.

- Coolant Tubes: Complex cooling systems require smooth, tight radius bends that minimize pressure drop while navigating around engine blocks, transmission housings, and accessory components, maintaining optimal coolant flow for temperature regulation.

- Intake and Charge Air Tubes: Performance depends on laminar airflow through bent sections that avoid turbulence and restriction, requiring precise mandrel tube bending that maintains consistent internal diameter throughout the curve for maximum efficiency.

- Engine and Transmission Oil Lines: High-pressure oil delivery systems demand bend quality that prevents stress concentrations and potential failure points, ensuring leak-free operation across temperature extremes and vibration cycles.

- Hydraulic Pressure and Suction Lines: Hydraulic systems need bent assemblies that handle high pressure differentials without collapsing or deforming, manufactured with controlled radii that preserve wall thickness and structural integrity throughout the bend.

- CNG and Propane Lines: Alternative fuel systems require specialized bending techniques that meet safety standards while accommodating routing requirements in confined engine bays, delivered with appropriate fittings and connection points.

Transform Your Design Requirements into Production Reality

When production schedules demand precision and reliability, partnering with experienced manufacturers makes the difference between success and costly delays. Our tube bending in Plymouth, Minnesota combines advanced equipment, technical expertise, and commitment to quality that keeps your projects moving forward.

Reach out today for expert guidance on your bent assembly needs.