Contact Us

Contact Us

RITZ Machine Works Inc. brings decades of precision manufacturing expertise to sheet metal fabrication in Brooklyn Park, Minnesota, serving OEMs and manufacturers who demand excellence. We combine laser cutting technology, CNC forming capabilities, and robotic welding to deliver custom sheet metal parts that meet the most demanding specifications.

Request a quote for your sheet metal fabrication project today.

Why Settling for Subpar Metal Components Puts Projects at Risk

Production delays caused by unreliable fabrication partners create cascading problems throughout your supply chain. When components arrive with poor tolerances or inconsistent quality, your team loses valuable time on rework, adjustments, and emergency sourcing from alternative suppliers.

We understand that your manufacturing success depends on partners who deliver precision work on schedule. Our ISO 9001:2015 registered facility eliminates these frustrations by combining rigorous quality control with advanced laser cutting and sheet metal fabrication technologies that ensure every component meets your exact specifications the first time.

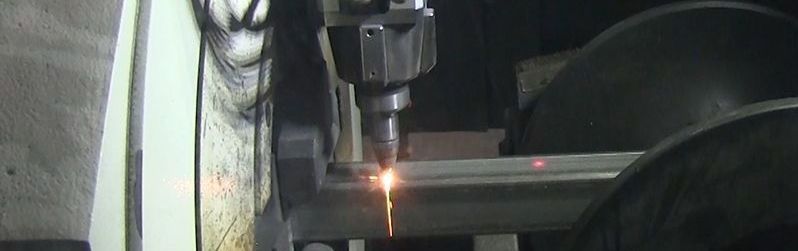

What Makes Modern Cutting Technology Essential for Your Projects?

Our fiber laser systems cut complex geometries in materials from thin gauge aluminum to heavy steel plate, maintaining tolerances that keep your assemblies fitting together perfectly. When your designs include detailed patterns, nested parts, or components requiring minimal heat distortion, our CNC-controlled laser cutting delivers the precision your sheet metal fabrication in Brooklyn Park, Minnesota demands.

Beyond basic cutting capabilities, we optimize material utilization to reduce waste and lower your component costs. Our programming expertise allows us to nest parts efficiently, maximize sheet usage, and process multiple thicknesses without tool changes.

How Does Expert Forming Create Structural Integrity?

Press brake operations require more than just bending metal between dies. Our CNC-controlled equipment delivers consistent angle accuracy across production runs, ensuring that brackets mount correctly, enclosures fit precisely, and structural components maintain their specified dimensions.

Whether your

sheet metal fabrication in Brooklyn Park, Minnesota needs involve simple 90-degree bends or complex multi-bend sequences, our programmable equipment handles challenging geometries while maintaining tight tolerances that keep your assemblies fitting together without modification.

Let's review your drawings and provide expert manufacturing guidance.

Seamless Solutions: Sheet Metal Fabrication in Brooklyn Park, Minnesota

Our CWB certified facilities maintain the quality standards essential for critical applications. When your projects demand sheet metal fabrication in Brooklyn Park, Minnesota that integrates seamlessly with other manufacturing processes, we deliver complete solutions that simplify your supply chain while maintaining the precision your applications require.

- MIG Welding Expertise: Our robotic MIG welding cells produce consistent, high-quality welds on production runs, eliminating the variability of manual welding while dramatically increasing throughput for repetitive assemblies.

- TIG Welding Precision: For stainless sheet metal work and applications requiring superior appearance or working with thin materials, our certified TIG welders deliver clean, precise joints that meet the most demanding cosmetic and structural requirements.

- Structural Assembly: We integrate bent tubing with fabricated sheet metal components to create complete weldments, combining our tube bending expertise with fabrication capabilities for turnkey solutions that arrive ready to install.

- Sub-Assembly Services: Rather than managing multiple suppliers for different manufacturing processes, consolidate your supply chain by partnering with us for complete sub-assemblies that reduce your internal handling and quality control requirements.

- Production Integration: Our understanding of both fabrication and assembly means we design for manufacturability from the start, optimizing joint locations, minimizing weld distortion, and ensuring that components assemble efficiently in your production environment.

Experience the Difference that Advanced Technology Makes

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Praesent volutpat, nunc eu vestibulum mollis, eros erat bibendum velit, eget faucibus est ipsum vitae nunc. Ut nec diam velit. Sed sit amet urna felis. Proin aliquet, mauris vitae gravida luctus, est quam vehicula nunc, in consectetur eros augue non nisi.

Discover how our precision capabilities support your production goals.