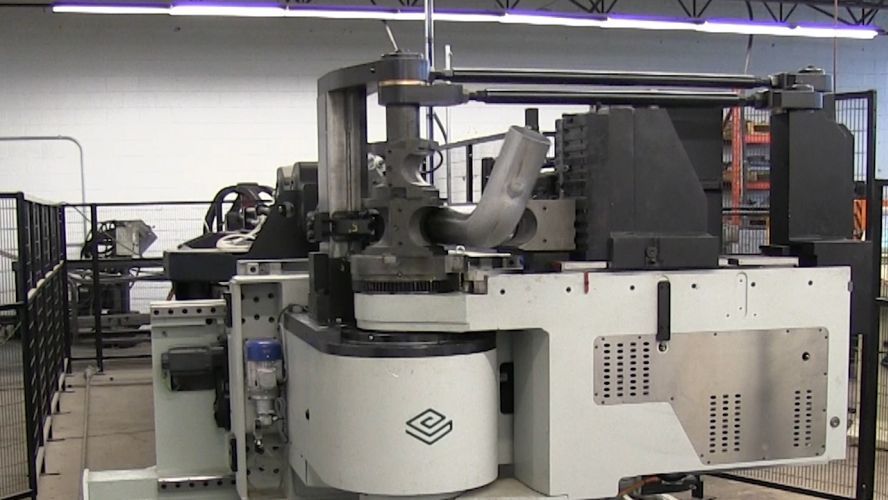

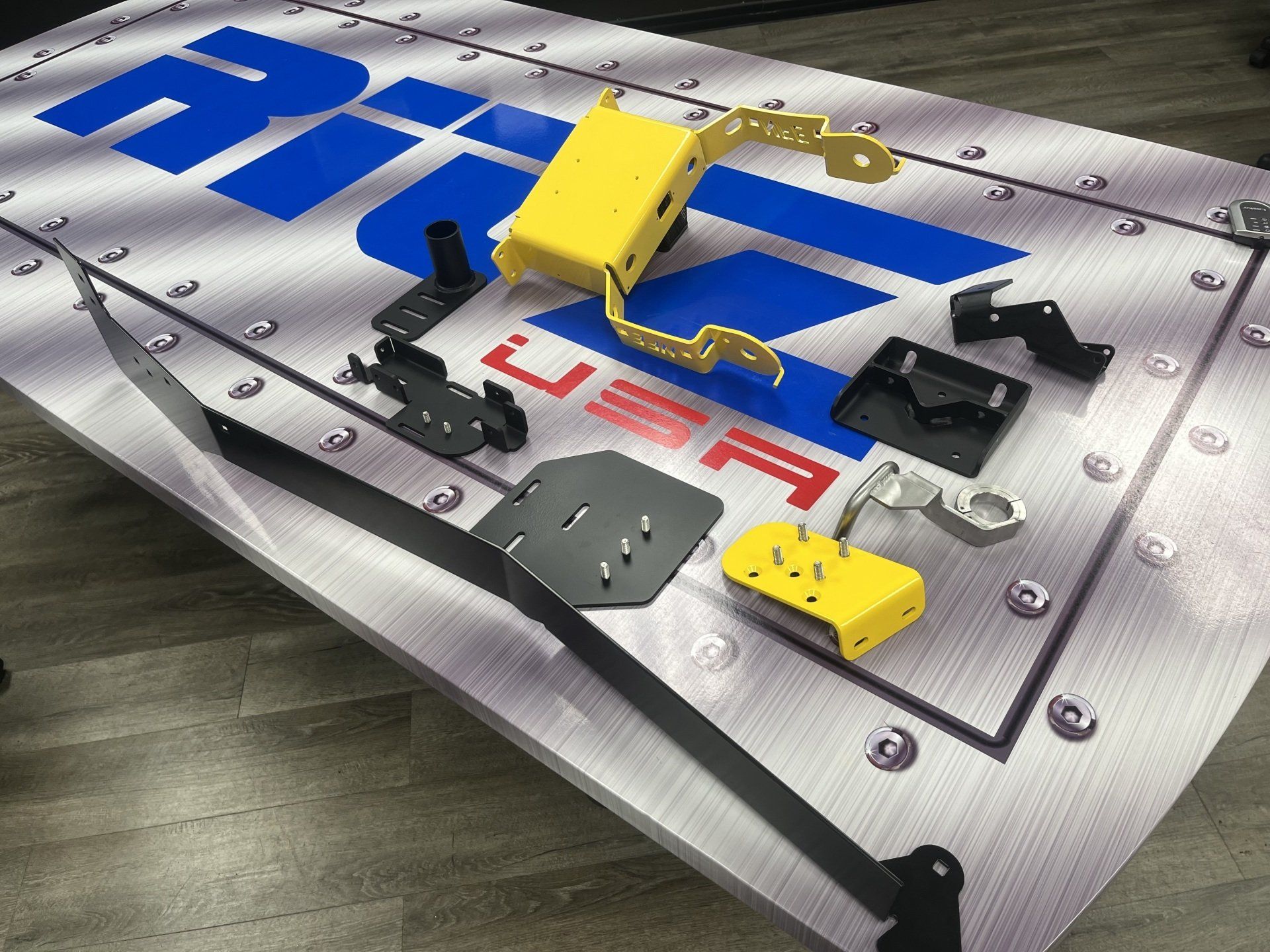

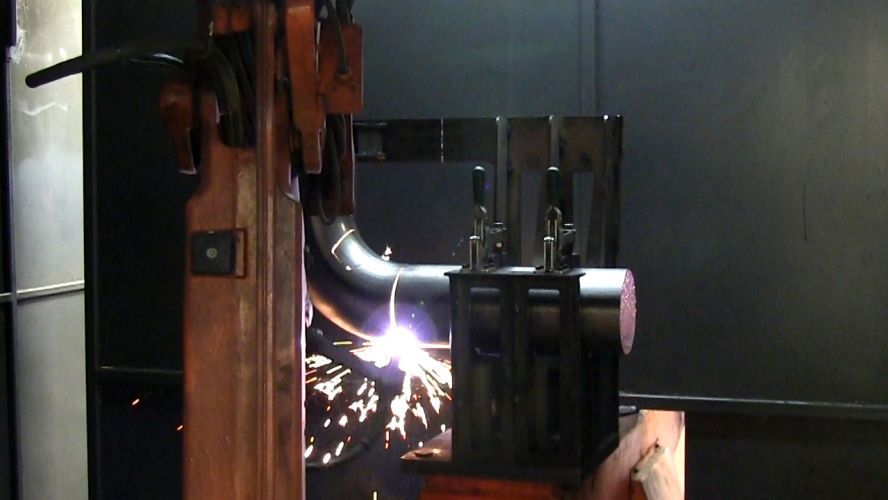

CAPABILITIES

We’re a “One Stop Tube Shop”, meaning our customers can count on us for all of their production tube bending and tubular assembly needs. With over 65,000 square feet of manufacturing and warehouse space between our Canadian and US plants, RITZ is ready to serve our customers by offering innovative and practical solutions.

Here are just a few of the state-of-the-art tools and processes we use to make your production requirements a part of our business.